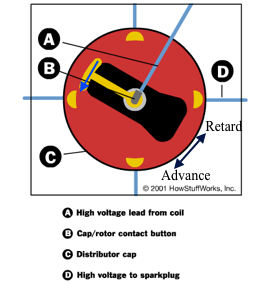

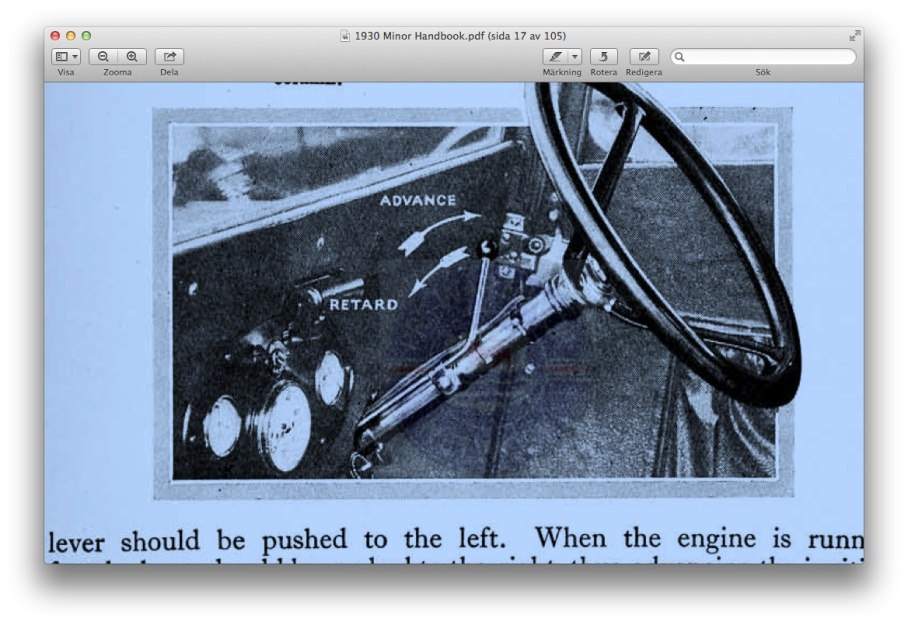

The aim of the manual ignition control is to get the driver full “control” over the engine performance. When started and at low speed (revs) the ignition should be low, i.e. the spark plugs is expected to fire off the fuel/air just before TDC (about 4-8 degrees before the piston reach the top). Warm engine and at higher revs the engine needs more advance ignition (say around 25-30 degrees before TDC) to perform at it’s best. By turning the distributor this advance/retard control is obtained.

(In more “modern” cars the ignition control is automatic, often controlled by the inlet vacuum or sometimes just mechanical adaptation (by springs and weights) to the engine revs.)

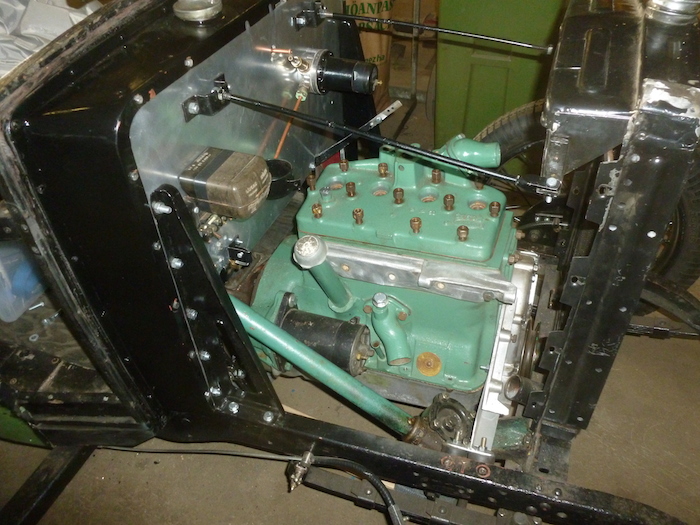

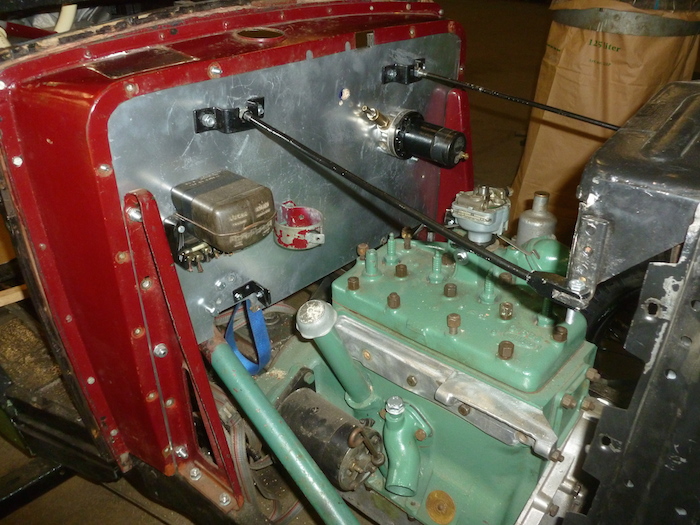

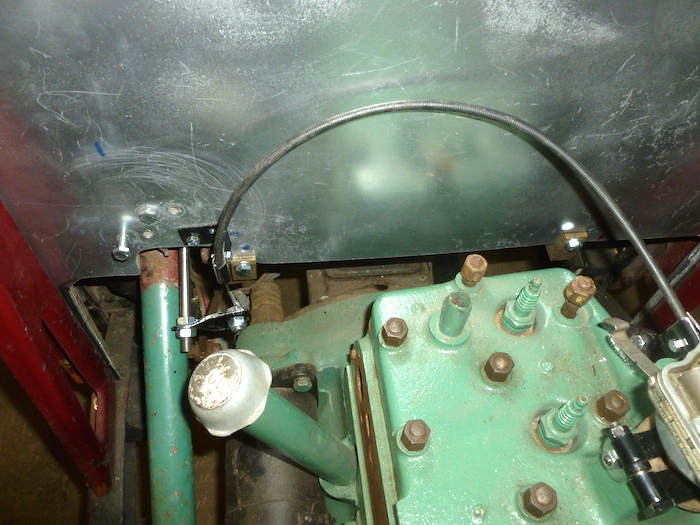

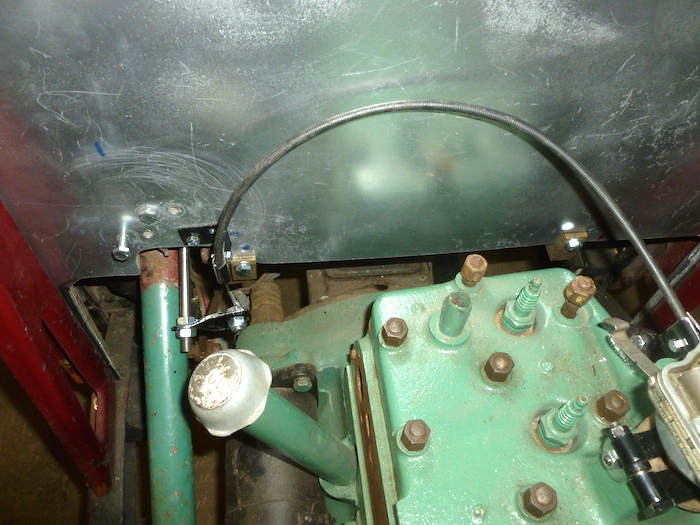

Because the engine moves during acceleration and retardation I needed a mechanical control that ignored these variations. Therefore I chosed cable control between the drivers control rod and the distributer. This solution needed among some other details design of a couple of brackets to fix the cable ends. And the cable itself must be stiff enough to work in both directions i.e. pull and push the distributor angle.

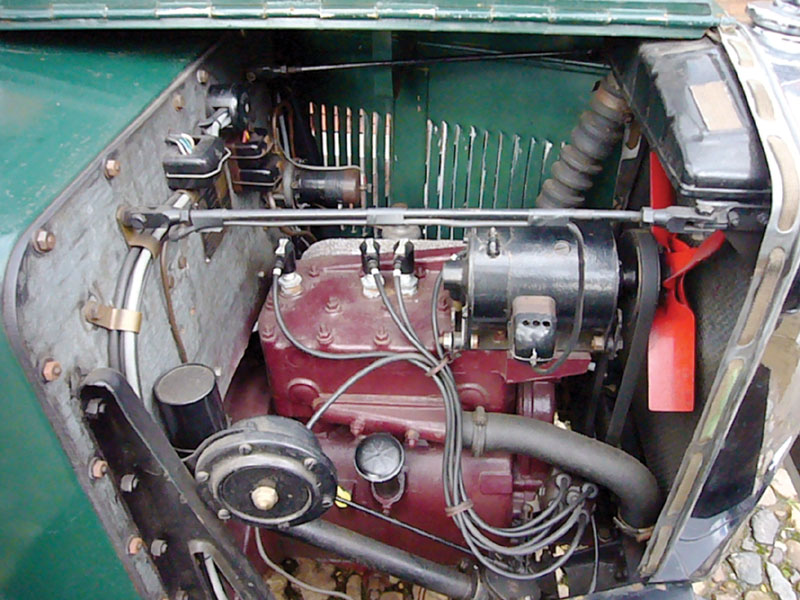

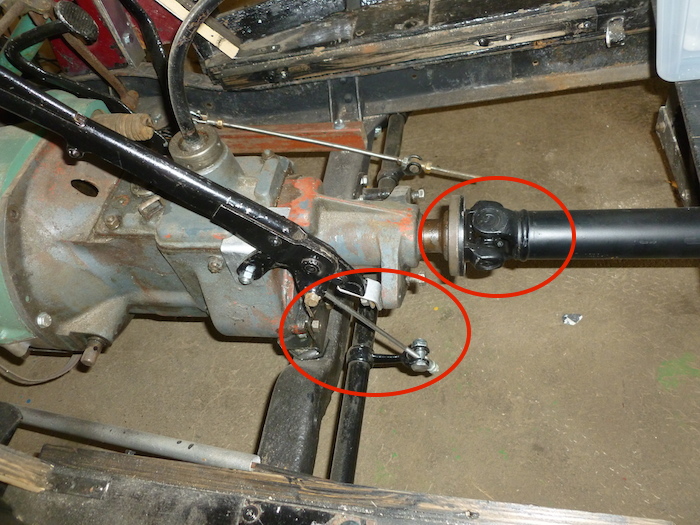

The connection from the drivers control rod and cable.

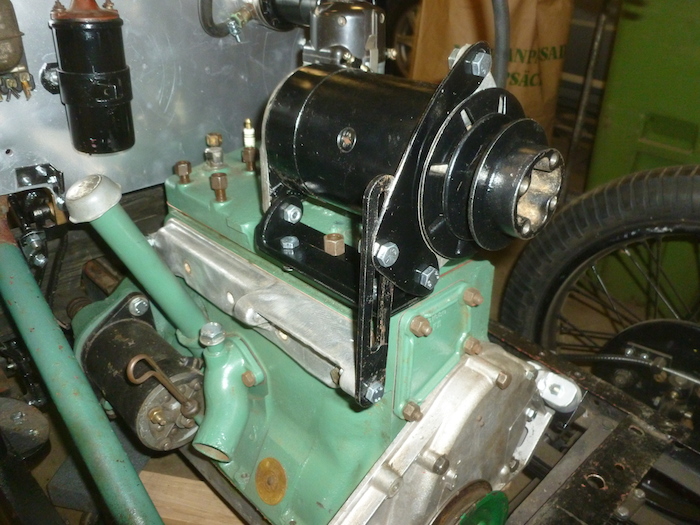

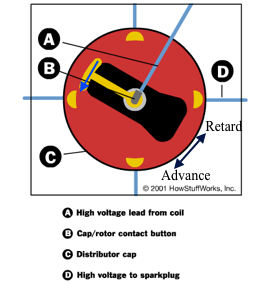

The connection cable to distributor. When the cable push the distributor the ignition is more advanced and vice versa.

The connection cable to distributor. When the cable push the distributor the ignition is more advanced and vice versa.

It´s then totally up to the driver to “feel and hear” and control the best angle for the distributor consider the speed and force needed at every moment. This is driving for real, isn´t it?